STR561 indicator with strain-gauge input is designed as a display for load cells and Melt pressure transducers (mV/V) and includes isolated power supply for the strain-gauge.

Conversion frequency programmable up to 1.2 KHz and resolution up to 24bit ensure high accuracy.

Different analog input calibration modes are selectable (sample weight, percent full-scale value, mV/V value).

Software features worth mentioning include multiple options for Tare management, Totalizer , Sum functions, process trend display with programmable time base or bar-graph with alarm/event thresholds.

An auto-configuration mode has also been implemented for some Dynisco Melt transducers, simplifying the settings required of the user.

Connectivity is provided by RS485 standard with Modbus RTU/Slave protocol.

STR561 interface is also quickly configurable via NFC with MyPixsys APP, without the need to power up the instrument or via multi-language text menus from the frontal keypad

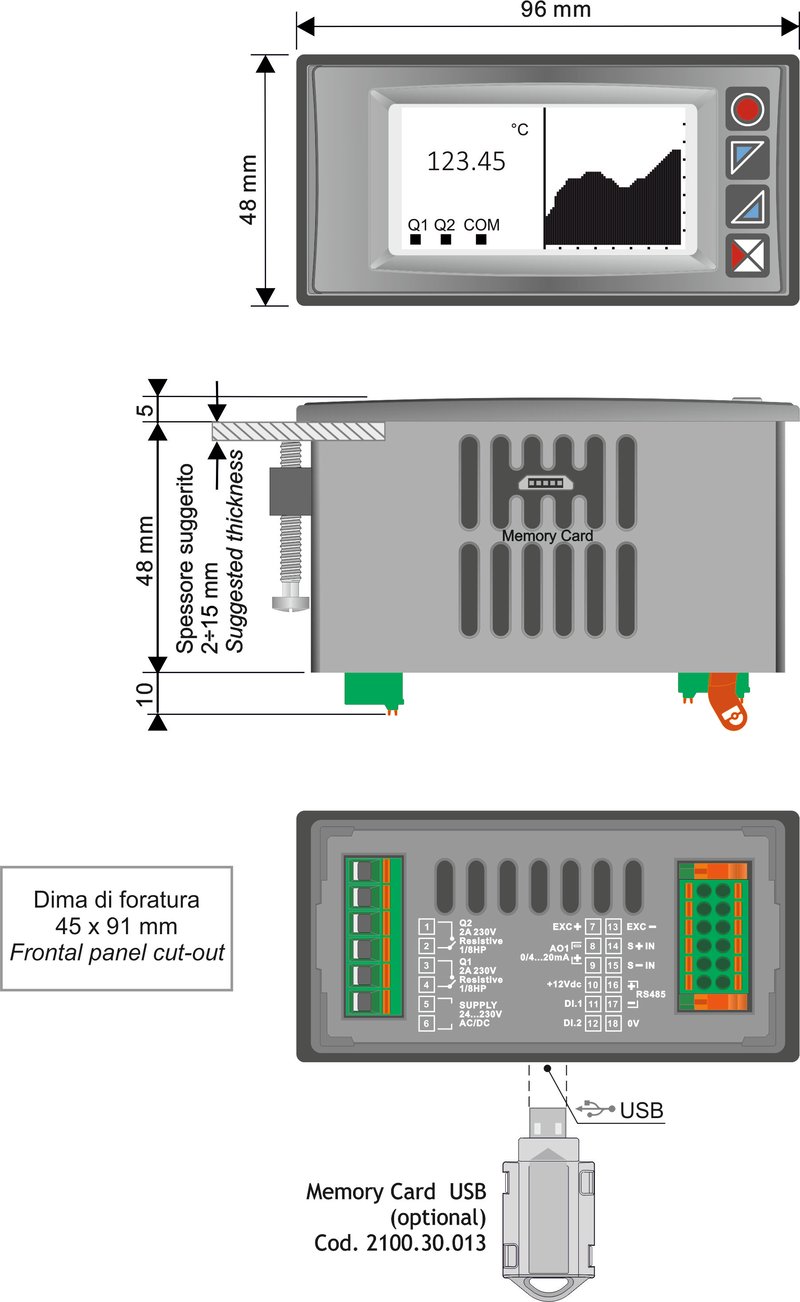

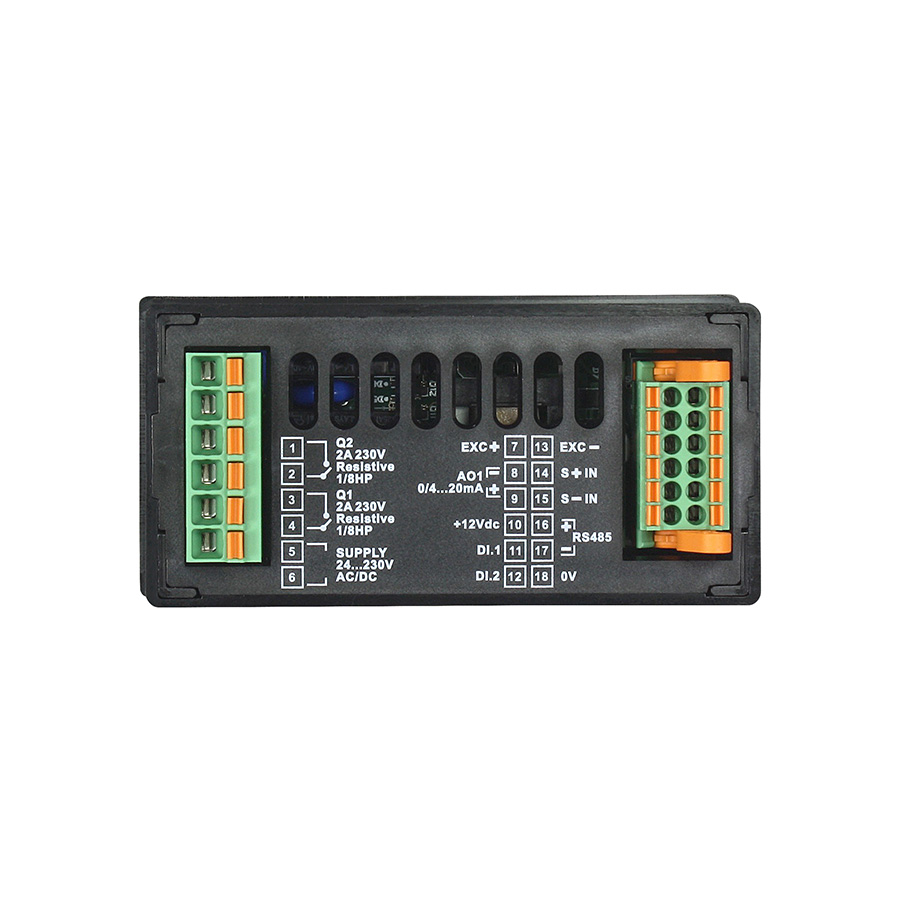

- Dimensions96x48 (Front panel) x 48 mm (1/8Din)

- MaterialBox: polycarbonate V0. Front cover: silicone rubber

- WeightApprox. 165 g

- SealingFront panel: IP54, Box and terminal blocks: IP20

- Operating conditionsTemperature 0..45 °C, humidity 35..95 RH%, max altitude 2000m

- CertificationsCE, UL

| ORDERING CODES | STR561-12ABC-T128R |

|---|---|

| Power supply | 24..230 V AC / DC ±15% 50/60 Hz - galvanic isolation 2,5KV |

| Power consumption | 8 Watt/Va |

| Display | 2.42" monochrome OLED graphic display (yellow), 128 x 64 |

| Analogue input for load cells | 1 x 23 bit (8000000 points). Max 2 350Ω parallel load-cells, or max 4 720Ω load-cells. - Linearity < 0.01% sul F.S. - Thermal drift < 0.001% sul F.S./°C - Max input signal 39 mV - Max load-cell sensibility 7mV/V Potentiometer: min. 200Ω (10000 points) with customizable linear input (max 16 steps) Impedance: |

| Sampling time | Configurable speed conversion from 1 Hz (8000000 points) to 1200 Hz (30000 points) |

| Digital inputs | 2x PNP, Run function, Hold, Alarm Reset, Lock alarm, Tara-Zero, Peak-Maximum/Peak-Peak Reset, Totaliser reset, Activate-Reset Sum, Parameters/Setpoint Lock, Net/Gross Weight Display |

| Analogue outputs | 1x output 0/4..20mA (60000 points) 1x 5VDC - 35mA max (strain gauge supply) |

| Auxiliary output | 12VDC - 30mA max for digital inputs |

| Relais outputs | 2x 2 A - 250 V AC resistive load |

| Serial communication | RS485 (1200..115200 Baud) galvanically isolated |

| USB | 1x micro USB |

- Alarms regulationON - OFF with hysteresis

- Alarm modeAbsolute / Threshold, Band with instantaneous/delayed/retentive/by digital input activation, Sensor failure / Activation by serial line

- Sum FunctionWith digital or keyboard input sum of different weights

- Totalizer FunctionVisualisation of instant process value and total value since last reset

- Trend visualizationTrend visualisation with selectable time basis from 0,1sec to 3600sec total 4K memory word

- Analogue retransmissionRetransmission of process values / setpoints to analogue output

- Digital transmission via RS485Retransmission of process values / setpoints / parameters on RS485 serial output

- Latch-on functionSemi-automatic limit learning procedure on cell input (sample value - mV/V value - % full-scale value)

- Multilingual menuEnglish/Italian/German/French/Spanish

- Measure unit visualizationSelection of the process unit to be displayed

- Data protectionLock of Command/Alarm Setpoints - Access to parameters by Password

- Communication protocolsModbus RTU