DRR460 is a single-loop PID controller, ideal for control/regulation of multi-zone systems.

An analog input is programmable for temperature sensors (resistance thermometers and thermocouples) and current or voltage signals.

Current monitoring is possible via dedicated TA input.

Two logic outputs are configurable for heating/cooling PID control loops or alarm functions. An analog output is also available for process control or retransmission.

Multiple software features include open/close logic for valve control and Soft-start for rise gradient control.

Programmable on PC by MyPixsysLab

Modbus-RTU and CANopen are the communication protocols available for serial connection to SCADA/supervisory systems.

The device meets control needs in a variety of industries: plastic extrusion, injection molding, packaging, ovens, textile machines and more generally multi-zone heat treatment plants.

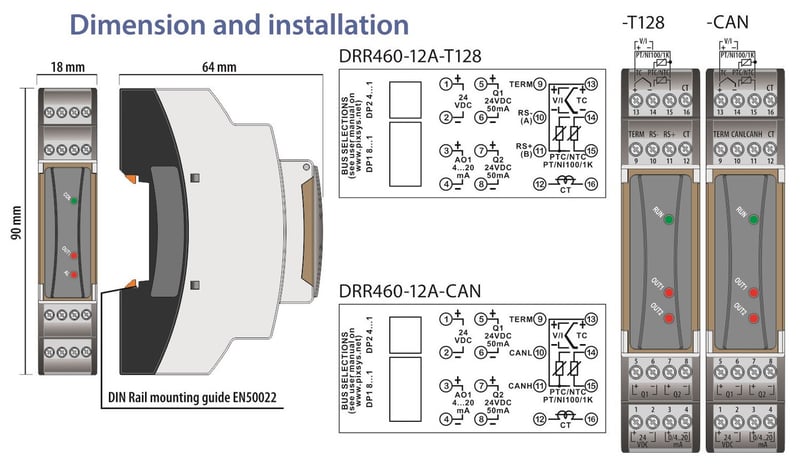

- Dimensions18 x 90 x 64 mm - 1 module DIN43880

- MaterialBox: Polycarbonate V0; Front panel: self-extinguishing silicone rubber V0

- WeightApprox. 210 g

- SealingBox and terminal blocks: IP20

- Operating conditionsTemperature 0..45 °C, humidity 35..95 RH%

- CertificationsCE, UL

|

ORDERING CODES |

DRR460-12A-T128 |

DRR460-12A-CAN |

|---|---|---|

|

Power supply |

24 V AC / DC ±15% 50/60 Hz - galvanic isolation 2,5KV |

|

|

Power consumption |

3 Watt/VA |

3 Watt/VA |

|

Analogue inputs |

1 x Ris. 16bit, programmable for thermocouples K, S, R, J, T, N, B (automatic compensation of the cold junction-25..85°C, ±0,2% F.S. ±1 digit F.S.), ThermoresistancesPT100, PT500, PT1000, Ni100, PTC1K, NTC10K (β 3435K), process signals 0..10 V (50000 points), 0/4..20mA (40000 points), 0..60 mV (25000 points), Potentiometer1..150 KΩ (50000 points) |

1 x Ris. 16bit, programmable for thermocouples K, S, R, J, T, N, B (automatic compensation of the cold junction-25..85°C, ±0,2% F.S. ±1 digit F.S.), ThermoresistancesPT100, PT500, PT1000, Ni100, PTC1K, NTC10K (β 3435K), process signals 0..10 V (50000 points), 0/4..20mA (40000 points), 0..60 mV (25000 points), Potentiometer1..150 KΩ (50000 points) |

|

Sampling time |

Programmable up to 2,1 ms (frequency up to 470 Hz) |

Programmable up to 2,1 ms (frequency up to 470 Hz) |

|

TA input |

1x T.A. 50 mA, 800 μs - 4096 points |

1x T.A. 50 mA, 800 μs - 4096 points |

|

Digital inputs |

- |

- |

|

Digital outputs |

2x 24 V DC - 30 mA max |

2x 24 V DC - 30 mA max |

|

Analogue outputs |

1x 0/4..20 mA, 34000 points ± 0,2% F.S. |

1x 0/4..20 mA, 34000 points ± 0,2% F.S. |

|

Serial communication |

RS485 (1200..115200 Baud) |

- |

|

CAN |

- |

CAN (50K..1Mbit) |

|

USB |

1x micro USB for programming via PC with MyPixsysLab |

1x micro USB for programming via PC with MyPixsysLab |

- Control algorithmsON - OFF with hysteresis, P., P.I., P.I.D., P.D. time-proportioned

- TuningManual or automatic

- Alarm modeAbsolute/ threshold, band, upper/lower deviation, Alarms with optional manual reset and activation delay, Loop Break Alarm

- Dual PIDHeating / cooling with dual PID

- Soft-StartRising gradient programmable as Degree / hour or fixed output %

- Open/Close logicsMotorised valves

- Software programmingSoftware MyPixsysLab

- Data protectionLock of Command/Alarm Setpoints - Access to parameters by Password

- Communication protocolsModbus RTU, CAN Open

- DRR460-12A-CAN1 MODULE DIN-BAR CONTROLLER

1 AI-1 AO-2 DO-CANOPEN-24VDC - DRR460-12A-T1281 MODULE DIN-BAR CONTROLLER

1 AI-1 AO-2 DO-RS485-24VDC